Question about adjustable cam gears

- Daftrusty

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 366

- Thanks: 199

Question about adjustable cam gears

30 Oct 2018 19:51

For some reason nobody makes adjustable cam gears for the kz/gpz750 motors. So I am forced to find somebody to mill out my spare set of kz750 gears. My question is....how much or how many degrees in either direction should I have them mill these out. I know that I might need at least 5° of leeway for the intake as the Yoshimura cams I need to install have a 110 installed lobe center, so for whatever reason if I want to set it to a more stock 105 I will need enough adjustment to do so.

So if anyone has knowledge of how this needs to be done, I would greatly appreciate any insight. If I do find someone to do this, they will more than likely have never seen a Kawasaki cam gear much less know what to do with it.

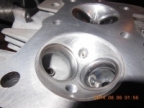

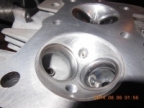

Picture to illustrate how the stock hyvo cam gears have ressesed areas that need to be milled out as well as slotting the bolt holes.

So if anyone has knowledge of how this needs to be done, I would greatly appreciate any insight. If I do find someone to do this, they will more than likely have never seen a Kawasaki cam gear much less know what to do with it.

Picture to illustrate how the stock hyvo cam gears have ressesed areas that need to be milled out as well as slotting the bolt holes.

1990 zr550

kz750e

650/750 6-speed Transmission Swap

kz750e

650/750 6-speed Transmission Swap

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: Question about adjustable cam gears

31 Oct 2018 05:17 - 31 Oct 2018 05:18

Speaking in sprocket degrees...

If the sprocket has 42 teeth, that's less than 9 degrees per tooth. Why would the slot have to be more than 9 degrees ? Wouldn't you just walk the chain over a tooth to go more than 9 deg?

If the sprocket has 42 teeth, that's less than 9 degrees per tooth. Why would the slot have to be more than 9 degrees ? Wouldn't you just walk the chain over a tooth to go more than 9 deg?

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Last edit: 31 Oct 2018 05:18 by loudhvx.

The following user(s) said Thank You: Kray-Z

Please Log in or Create an account to join the conversation.

- Wozza

-

- Offline

- User

-

Registered

- Posts: 136

- Thanks: 30

Re: Question about adjustable cam gears

31 Oct 2018 05:52 - 31 Oct 2018 06:09

I thought that if you want a 5 degree change on the crank degree wheel you would slot the cam gear for 2.5 degrees of movement

Maybe only 3-4mm on such a small PCD .

Maybe only 3-4mm on such a small PCD .

1982 KZ550H1

Last edit: 31 Oct 2018 06:09 by Wozza.

Please Log in or Create an account to join the conversation.

- KZB2 650

-

- Offline

- User

-

Registered

- Posts: 1472

- Thanks: 264

Re: Question about adjustable cam gears

31 Oct 2018 06:00

I remember reading that you go half the hole size each way and I suppose you could go a hair more just to be safe .... was gonna do mine but decided not to ..... the pic looks like they went way more than that..... maybe take a look on Ape's site to get a idea on the ones they sell (sure someone who knows for sure and will soon chime in).. Have read some do it with a dremel but I don't like that idea,,,,,, you could be off .005 pretty easy and get wobble I would think so having yours milled sound like the way to go.

1978 KZ650 b-2

700cc Wiseco kit 10 to 1.

1980 KZ750 cam, ape springs, stock clutch/ Barnett springs.

Vance and Hines Header w/ comp baffle and Ape pods, Dyna S and green coils, copper wires.

29MM smooth bores W/ 17.5 pilots, 0-6s and 117.5 main

16/42 gearing X ring chain and alum rear JT sprocket.

700cc Wiseco kit 10 to 1.

1980 KZ750 cam, ape springs, stock clutch/ Barnett springs.

Vance and Hines Header w/ comp baffle and Ape pods, Dyna S and green coils, copper wires.

29MM smooth bores W/ 17.5 pilots, 0-6s and 117.5 main

16/42 gearing X ring chain and alum rear JT sprocket.

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: Question about adjustable cam gears

31 Oct 2018 06:04 - 31 Oct 2018 06:05

It shouldn't wobble. The centering of the sprocket is done by the mating surface on the camshaft.

But I agree, the photo looks far more slotted than I would have expected.

But I agree, the photo looks far more slotted than I would have expected.

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Last edit: 31 Oct 2018 06:05 by loudhvx.

The following user(s) said Thank You: KZB2 650

Please Log in or Create an account to join the conversation.

- KZB2 650

-

- Offline

- User

-

Registered

- Posts: 1472

- Thanks: 264

Re: Question about adjustable cam gears

31 Oct 2018 06:28loudhvx wrote: It shouldn't wobble. The centering of the sprocket is done by the mating surface on the camshaft.

But I agree, the photo looks far more slotted than I would have expected.

Dang Loud I should a noticed or thought of that when I switched the stock 650 gears with the 750 gears....... I might a done em them then.......... maybe at a later time then.

1978 KZ650 b-2

700cc Wiseco kit 10 to 1.

1980 KZ750 cam, ape springs, stock clutch/ Barnett springs.

Vance and Hines Header w/ comp baffle and Ape pods, Dyna S and green coils, copper wires.

29MM smooth bores W/ 17.5 pilots, 0-6s and 117.5 main

16/42 gearing X ring chain and alum rear JT sprocket.

700cc Wiseco kit 10 to 1.

1980 KZ750 cam, ape springs, stock clutch/ Barnett springs.

Vance and Hines Header w/ comp baffle and Ape pods, Dyna S and green coils, copper wires.

29MM smooth bores W/ 17.5 pilots, 0-6s and 117.5 main

16/42 gearing X ring chain and alum rear JT sprocket.

Please Log in or Create an account to join the conversation.

- Daftrusty

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 366

- Thanks: 199

Re: Question about adjustable cam gears

31 Oct 2018 08:11 - 31 Oct 2018 08:18

I also thought that the pictured cam gear had a unnessasary amount of adjustment milled into it, but I didn’t know for sure. Most aftermarket adjustable sprockets seem to have almost as much, but I don’t have one to measure.

I liked the idea of elongating the holes half of the bolt diameter each way, so I measured the hole and it is 6.5mm. So elongating it ~3mm each way for a total of 12-13mm. (The recesses around the bolt holes are exactly 13mm oddly enough. ) But when I drew it out on the gear, it seems that only gives me about 1.5 teeth of movement each way. Does that seem like enough, or am I miss understanding the issue?

****EDIT*****

Ok...So I just got off the phone with APE and he said that they elongate the holes "just over a tooth" as he said if you run out of adjustment room, you can just move the chain over one tooth. That is kind of a hassle but makes perfect sense!

I liked the idea of elongating the holes half of the bolt diameter each way, so I measured the hole and it is 6.5mm. So elongating it ~3mm each way for a total of 12-13mm. (The recesses around the bolt holes are exactly 13mm oddly enough. ) But when I drew it out on the gear, it seems that only gives me about 1.5 teeth of movement each way. Does that seem like enough, or am I miss understanding the issue?

****EDIT*****

Ok...So I just got off the phone with APE and he said that they elongate the holes "just over a tooth" as he said if you run out of adjustment room, you can just move the chain over one tooth. That is kind of a hassle but makes perfect sense!

1990 zr550

kz750e

650/750 6-speed Transmission Swap

kz750e

650/750 6-speed Transmission Swap

Last edit: 31 Oct 2018 08:18 by Daftrusty.

Please Log in or Create an account to join the conversation.

- Nebr_Rex

-

- Offline

- User

-

Registered

- Posts: 1888

- Thanks: 295

Re: Question about adjustable cam gears

31 Oct 2018 17:43

I have a Bridgeport and the tooling. Milling a sprocket would be no problem.

Look at the link in my signature. I'm working on the KZ400/440 twins.

The KZ440 sprocket can be swapped with the KZ750 /4. What I have done

is modify the KZ440 to 'enhance' performance. I just drilled and milled the

sprocket at a set number of degrees. Milling a slot would be no problem.

I can modify practically any motorcycle cam sprocket.

.

Look at the link in my signature. I'm working on the KZ400/440 twins.

The KZ440 sprocket can be swapped with the KZ750 /4. What I have done

is modify the KZ440 to 'enhance' performance. I just drilled and milled the

sprocket at a set number of degrees. Milling a slot would be no problem.

I can modify practically any motorcycle cam sprocket.

.

2002 ZRX1200R

81 GPz1100

79 KZ1000st daily ride

79 KZ1000mk2 prodject

78 KZ650sr

78 KZ650b

81 KZ750e

80 KZ750ltd

77 KZ400/440 cafe project

76 KZ400/440 Fuel Injected

www.dotheton.com/forum/index.php?topic=39120.0

.

81 GPz1100

79 KZ1000st daily ride

79 KZ1000mk2 prodject

78 KZ650sr

78 KZ650b

81 KZ750e

80 KZ750ltd

77 KZ400/440 cafe project

76 KZ400/440 Fuel Injected

www.dotheton.com/forum/index.php?topic=39120.0

.

The following user(s) said Thank You: KZB2 650, Kray-Z, Wozza

Please Log in or Create an account to join the conversation.

- Daftrusty

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 366

- Thanks: 199

Re: Question about adjustable cam gears

01 Nov 2018 05:05Nebr_Rex wrote: I have a Bridgeport and the tooling. Milling a sprocket would be no problem.

Look at the link in my signature. I'm working on the KZ400/440 twins.

The KZ440 sprocket can be swapped with the KZ750 /4. What I have done

is modify the KZ440 to 'enhance' performance. I just drilled and milled the

sprocket at a set number of degrees. Milling a slot would be no problem.

I can modify practically any motorcycle cam sprocket.

.

That would be fantastic! After reading through your KZ440 thread I realize you are over qualified for the task.

This saves me from having to draw up a explanation of what I need to a local machinist. The last time I did that he waited a month to start the project and managed to lose my written instructions and CAD drawing.

I will PM you.

1990 zr550

kz750e

650/750 6-speed Transmission Swap

kz750e

650/750 6-speed Transmission Swap

Please Log in or Create an account to join the conversation.

- Kray-Z

-

- Offline

- User

-

Registered

- I need more power Scotty....

- Posts: 583

- Thanks: 107

Re: Question about adjustable cam gears

01 Nov 2018 22:15

Hey Daftrusty - happy to see you are still here on KZR.

The point raised by loudhvx is important - the slot arc length only has to cover about +0.020" more than the angle between the cam gear/sprocket tooth spacing, centered on the original holes. This is easily done on a standard vertical milling machine with a rotary table and 2 sizes of milling cutters (one to clear the bolt and one to clear the bolt head flange) . If there are 42 teeth, the angle to cut is 360/42 = 8.57 degrees on the rotary table, plus 0.020" at both ends, so 10 degrees should be ample. If you find you can't get the cams where you want with that much adjustment in the slots, just move the chain to the next tooth and try again. As always, but even more importantly with slotted cam wheels, use only high strength (Class 10.9 or better, 12.9) top quality NEW flanged bolts and blue or red loctite on the threads (apply the loctite after you have the cam sprockets correctly degreed with your old bolts by removing one bolt at a time, applying loctite to a NEW bolt, then torque bolt, rotate cam, remove second old bolt, apply loctite on NEW bolt, and install. One more time if your cams use three bolts).

Positively awesome that Nebr_Rex offered to do this for you! That is what this community is for - helping each other as best we can. Thanks Nebr_Rex!

The point raised by loudhvx is important - the slot arc length only has to cover about +0.020" more than the angle between the cam gear/sprocket tooth spacing, centered on the original holes. This is easily done on a standard vertical milling machine with a rotary table and 2 sizes of milling cutters (one to clear the bolt and one to clear the bolt head flange) . If there are 42 teeth, the angle to cut is 360/42 = 8.57 degrees on the rotary table, plus 0.020" at both ends, so 10 degrees should be ample. If you find you can't get the cams where you want with that much adjustment in the slots, just move the chain to the next tooth and try again. As always, but even more importantly with slotted cam wheels, use only high strength (Class 10.9 or better, 12.9) top quality NEW flanged bolts and blue or red loctite on the threads (apply the loctite after you have the cam sprockets correctly degreed with your old bolts by removing one bolt at a time, applying loctite to a NEW bolt, then torque bolt, rotate cam, remove second old bolt, apply loctite on NEW bolt, and install. One more time if your cams use three bolts).

Positively awesome that Nebr_Rex offered to do this for you! That is what this community is for - helping each other as best we can. Thanks Nebr_Rex!

2-04 R1, 81 CSR1000, 81 LTD1000, 2-83 GPz1100, 3-79CBX, 81 CBX, 3-XS650, 84 Venture, +parts

Quote "speed costs money...how fast do you want to go?" (Which Z movie?)

Universal formula for how many motorcycles one should own = n + 1, where n is how many motorcycles you own right now....

Quote "speed costs money...how fast do you want to go?" (Which Z movie?)

Universal formula for how many motorcycles one should own = n + 1, where n is how many motorcycles you own right now....

Please Log in or Create an account to join the conversation.

- Daftrusty

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 366

- Thanks: 199

Re: Question about adjustable cam gears

02 Nov 2018 07:27 - 02 Nov 2018 07:31Kray-Z wrote: Hey Daftrusty - happy to see you are still here on KZR.

The point raised by loudhvx is important - the slot arc length only has to cover about +0.020" more than the angle between the cam gear/sprocket tooth spacing, centered on the original holes. This is easily done on a standard vertical milling machine with a rotary table and 2 sizes of milling cutters (one to clear the bolt and one to clear the bolt head flange) . If there are 42 teeth, the angle to cut is 360/42 = 8.57 degrees on the rotary table, plus 0.020" at both ends, so 10 degrees should be ample. If you find you can't get the cams where you want with that much adjustment in the slots, just move the chain to the next tooth and try again. As always, but even more importantly with slotted cam wheels, use only high strength (Class 10.9 or better, 12.9) top quality NEW flanged bolts and blue or red loctite on the threads (apply the loctite after you have the cam sprockets correctly degreed with your old bolts by removing one bolt at a time, applying loctite to a NEW bolt, then torque bolt, rotate cam, remove second old bolt, apply loctite on NEW bolt, and install. One more time if your cams use three bolts).

Positively awesome that Nebr_Rex offered to do this for you! That is what this community is for - helping each other as best we can. Thanks Nebr_Rex!

Kray-Z you bring up many good points! Especially the bolts. I was so focused on setting them correctly, that I never stopped to consider that the bolts have to be up to the task of preventing slippage as well as holding it all together.

But since I am learning as we go and for others who may read this who are doing the same, I need to ask some more questions.

Also I printed out one of Loudhvx's handy degree wheels for the cam gear and was using this for reference while following along. But I kept getting 7.5°~8° between teeth and everyone else was referencing 9°. Then it dawned on me that the 750's use a 46 tooth gear, not 42.

So 360/46 is 7.8°....... so now I can stop worrying that my measurements didn't match everyone else's.

1. So is the ultimate goal to only slot the gear to give one tooth of adjustment? (This is in both directions correct?)

2. Is this because (as Loudhvx and APE pointed out) that if I run out of adjustment I just move the chain over a tooth thus making it unnecessary to mill the slot any larger?

3. So for 7.8° + .020", what is a safe round number? 9°... 10°?? ( Once again, this needs to be done in both directions??)

4. What is the extra .020" at the end of each slot for just out of curiosity? To make room for any manufacturing discrepancies in the bolt or rotary table?

4. Does the stock cam bolt torque value still apply, or does it need to be higher?

I apologize if these are remedial questions, but Nebr_Rex asked me for specifics, and I only answered him with a vague guess.

1990 zr550

kz750e

650/750 6-speed Transmission Swap

kz750e

650/750 6-speed Transmission Swap

Last edit: 02 Nov 2018 07:31 by Daftrusty.

Please Log in or Create an account to join the conversation.

- Kray-Z

-

- Offline

- User

-

Registered

- I need more power Scotty....

- Posts: 583

- Thanks: 107

Re: Question about adjustable cam gears

02 Nov 2018 09:38Daftrusty wrote:Kray-Z wrote: Hey Daftrusty - happy to see you are still here on KZR.

The point raised by loudhvx is important - the slot arc length only has to cover about +0.020" more than the angle between the cam gear/sprocket tooth spacing, centered on the original holes. This is easily done on a standard vertical milling machine with a rotary table and 2 sizes of milling cutters (one to clear the bolt and one to clear the bolt head flange) . If there are 42 teeth, the angle to cut is 360/42 = 8.57 degrees on the rotary table, plus 0.020" at both ends, so 10 degrees should be ample. If you find you can't get the cams where you want with that much adjustment in the slots, just move the chain to the next tooth and try again. As always, but even more importantly with slotted cam wheels, use only high strength (Class 10.9 or better, 12.9) top quality NEW flanged bolts and blue or red loctite on the threads (apply the loctite after you have the cam sprockets correctly degreed with your old bolts by removing one bolt at a time, applying loctite to a NEW bolt, then torque bolt, rotate cam, remove second old bolt, apply loctite on NEW bolt, and install. One more time if your cams use three bolts).

Positively awesome that Nebr_Rex offered to do this for you! That is what this community is for - helping each other as best we can. Thanks Nebr_Rex!

Kray-Z you bring up many good points! Especially the bolts. I was so focused on setting them correctly, that I never stopped to consider that the bolts have to be up to the task of preventing slippage as well as holding it all together.

But since I am learning as we go and for others who may read this who are doing the same, I need to ask some more questions.

Also I printed out one of Loudhvx's handy degree wheels for the cam gear and was using this for reference while following along. But I kept getting 7.5°~8° between teeth and everyone else was referencing 9°. Then it dawned on me that the 750's use a 46 tooth gear, not 42.

So 360/46 is 7.8°....... so now I can stop worrying that my measurements didn't match everyone else's.

1. So is the ultimate goal to only slot the gear to give one tooth of adjustment? (This is in both directions correct?)

2. Is this because (as Loudhvx and APE pointed out) that if I run out of adjustment I just move the chain over a tooth thus making it unnecessary to mill the slot any larger?

3. So for 7.8° + .020", what is a safe round number? 9°... 10°?? ( Once again, this needs to be done in both directions??)

4. What is the extra .020" at the end of each slot for just out of curiosity? To make room for any manufacturing discrepancies in the bolt or rotary table?

4. Does the stock cam bolt torque value still apply, or does it need to be higher?

I apologize if these are remedial questions, but Nebr_Rex asked me for specifics, and I only answered him with a vague guess.

Hey Rusty, always willing to help when I have the time…

Answers:

1. You only need one tooth plus a bit (add no less than 0.020” each way) worth of cut sweep to get the job done. This minimizes the material removed and keeps gear strong and the slot from spreading open.

2. Yes, you can move ½ way towards the gear tooth spacing angle in both directions with the gear angle length slots. If that isn’t enough, just move the chain to the next tooth and sweep the bolt in the opposite direction in the slot.

3. With 46 teeth, 10 or 12 degree slots (5 or 6 degrees each way from center) are easy to remember when reading/ setting the dial on the rotary table, and won’t be greatly oversized.

4. Stick with the middle of the stock torque spec, if you trust your current torque wrench.

Just remember to have at least Class 10.9 flanged bolts on hand. I keep a drawer full of 12.9 M6x1.0 Flanged bolts on hand for the KZ’s (I don’t remember the length off hand, but I think they are 10 mm long, maybe 12). Even loosening them once will need to be loctited again. With Red Loctite (I use blue myself for the Japanese stuff and reserve red for Harleys, old brit bikes and such), the bolts should be replaced again after being loctited and torqued a few times – don’t re-use the bolts more than 4 times regardless. The valves might hit each other and / or the high compression pistons if both the sprockets ever work loose, even with stock cams.

Happy Tuning Buddy!

2-04 R1, 81 CSR1000, 81 LTD1000, 2-83 GPz1100, 3-79CBX, 81 CBX, 3-XS650, 84 Venture, +parts

Quote "speed costs money...how fast do you want to go?" (Which Z movie?)

Universal formula for how many motorcycles one should own = n + 1, where n is how many motorcycles you own right now....

Quote "speed costs money...how fast do you want to go?" (Which Z movie?)

Universal formula for how many motorcycles one should own = n + 1, where n is how many motorcycles you own right now....

The following user(s) said Thank You: Daftrusty

Please Log in or Create an account to join the conversation.

Moderators: Street Fighter LTD